Lean Process Improvement

Lean centres on encouraging skilled and motivated people across the organisation to work together to improve the efficiency of processes. Understand the concepts at the heart of the lean philosophy, and consider its application within your organisation.

£100 +VAT

Lean Process Improvement

£100 +VAT

Lean Process Improvement

This course is not currently available. To find out more, please get in touch.

This course will enable you to

- Understand the benefits of the lean philosophy

- Establish the starting point and stages in a lean improvement project

- Define value stream mapping (VSM), and the outcome you wish to achieve in an improvement project

- Understand the principles of good process design and the key tools of lean improvement

- Structure your organisation’s lean improvement efforts, including the composition of an improvement team and the stages that the improvement team should work through

About the course

Lean is a philosophy. It centres on encouraging skilled and motivated people across the organisation to work together to improve the efficiency of processes. It allows us to create a system where we can use time we used to spend rectifying mistakes on more profitable activities.

The approach has gained tremendous traction over the last 15 years, and organisations all over the world are now applying the principles of lean improvement. Nevertheless, lean remains something of an enigma – many people do not fully understand its core philosophy. The efficiencies gained from lean improvement can be used to serve more customers and develop new products and services.

Now enhanced with additional case studies and video interviews with the author, this course will help you to understand the concepts and beliefs at the heart of the lean philosophy, and to think through its application within your organisation.

Contents

What is lean?

The history of lean

What is lean?

Why choose lean?

People vs tools

The doctrine of marginal gains

Five principles of lean

Principles of the lean philosophy

The lean improvement plan

The improvement team

Customer value and waste

The voice of the customer

What does the customer want?

Defining value

Work that doesn’t add value

The nine wastes

Cost impacts of waste

Lean in the real world

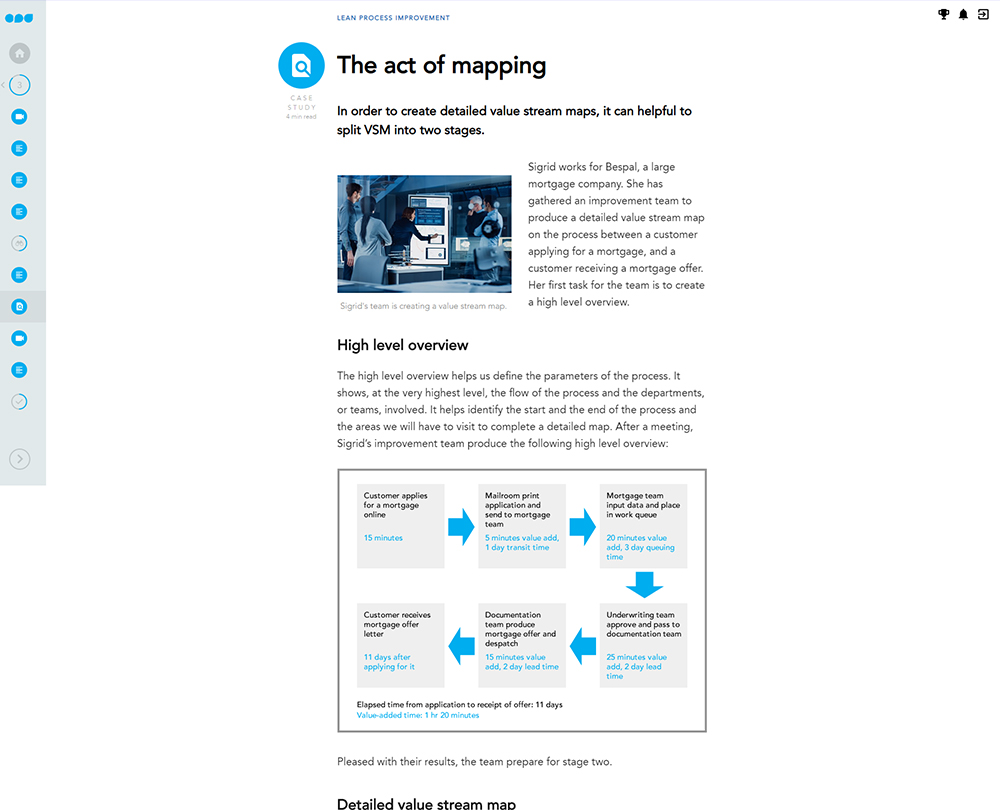

Mapping the value stream

Defining the value stream

Value streams

The voice of the process

Value stream mapping

VSM symbols

VSM tips

Problem statements and goal statements

A culture of improvement

Creating the right culture

Getting the most from your team

Empowering and engaging people

Measuring success

Resistance to change

Overcoming resistance

Reviewing problems

Improving the process

Process problem analysis

Lean improvement tools

Lean process design principles

Testing solutions

Creating the right structure

Creating a structure

Structural elements

Coordinating the process

Improving the improvement team

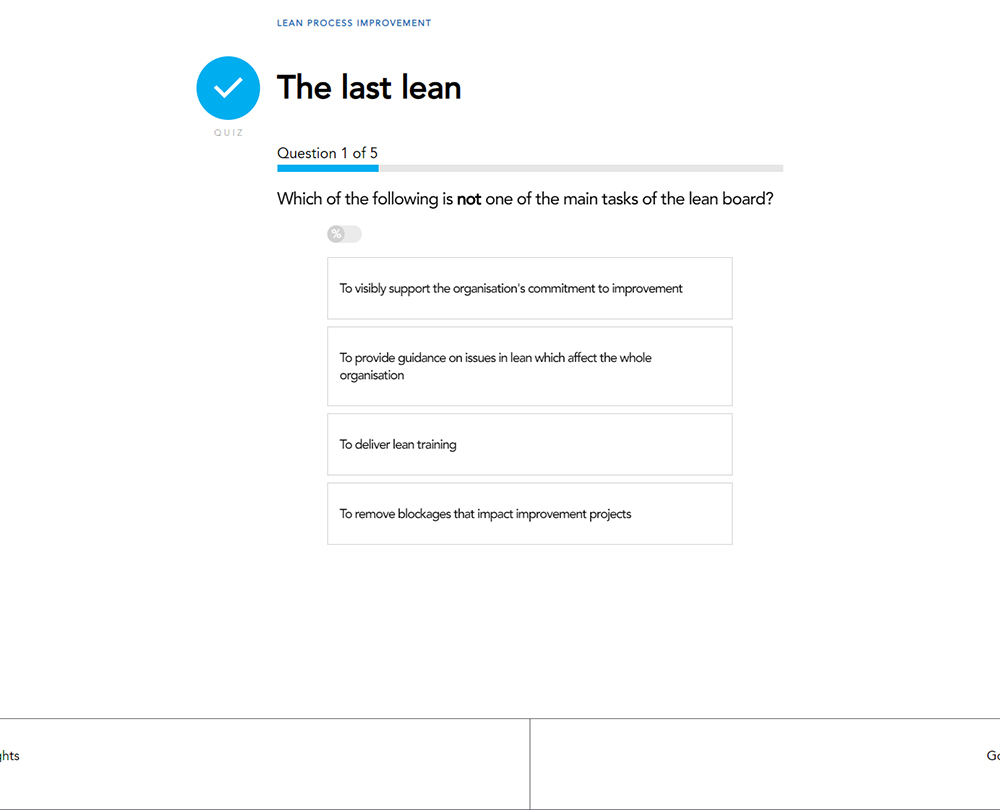

Developing an improvement plan

Dealing with difficult issues

Closing the project

Making time for improvements

Getting started

Final thoughts

How it works

Author

Ross Maynard

Ross has worked as a consultant and trainer for over 20 years, specialising in finance processes, management information and performance measurement. He supports organisations to understand their processes; facilitates improvement teams; and supports staff to work together as a team to deliver tangible and sustainable improvements.

You might also like

Take a look at some of our bestselling courses